Discover the value and relevant applications within the manufacturing industry

All major research agencies (Gartner, McKinsey, Deloitte) agree. Augmented Reality is going to bring about a lot of change in the manufacturing industry. The first successful cases are up and running and are creating a lot of curiosity. For us the reason to write this blog post. A few years ago during the introduction of the Microsoft Hololens we took the first serious steps in Augmented Reality (AR) and Mixed Reality (MR). Since then we have been helping organisations on their way in the world of both Augmented Reality (AR) and Mixed Reality (MR). Because especially in this sector, the possibilities are unprecedented.

Every day we see the added value AR can offer the manufacturing industry. This has inspired us to define and explain important use cases. To get you thinking and to let you come up with new applications within your organization.

Short introduction

Augmented reality is the application of real-time information in the form of text, image, audio or other virtual enrichments that is laid as a layer over objects in reality. (Gartner)

Through the camera or a transparent screen you see the world around you. Then extra information is added to your view. This can be done because cameras can recognise areas through points. These points and planes together form a 3D map of the environment. Ready for interaction. On the basis of a number of practical applications we like to tell something about the possibilities.

1. Maintenance and repairs

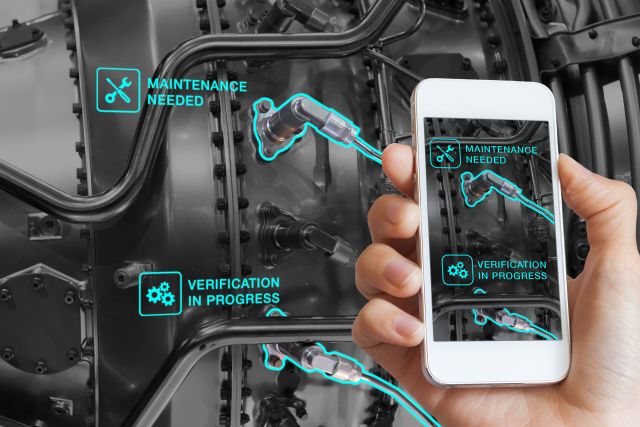

Maintenance and repairs often require specialist knowledge. Organisations often need external experts to carry out this maintenance. This ensures that in case of calamities, production lines often come to a standstill for a long time until the external expert is present. Faster action and thus avoiding unnecessary costs can offer a solution to this problem. Augmented Reality gives operators the tools to carry out small repairs or maintenance work themselves (possibly with an expert who instructs and monitors remotely). Objects and machines can be recognized automatically. Would you like to know more about how we can recognize objects? Do you want to know more about recognizing objecs?

Small maintenance

Operators work with special glasses or tablets which not only show the efficiency of the production line but also the maintenance that needs to be done. When, for example, the packing machine needs to be lubricated, the operator receives a notification. When he is on site, the lubrication points are highlighted. Next to the highlights it is also possible to provide extra information/instructions by means of audio or text.

Calamities or major maintenance

In case of complicated repairs or maintenance it is also possible to have someone take a look with you. For example, an operator or junior mechanic supported by an experienced mechanic can remotely do complex repairs himself. AR shortens breakdown and maintenance times, guarantees production continuity and increases the self-sufficiency of the operators.

2. Product visualization

When developing new products, it is necessary to ensure that they meet current customer needs. By bringing 3D/CAD models of the R&D department to life through AR, product designs can be tested. Any errors in the product can be detected and eliminated at an early stage. Not having to make a physical prototype directly also saves money and time.

It can also be very valuable for customers to be able to place the virtual models in the physical world; because they can place the product of their interest in their own environment or give it just that color or print that they like, they are more likely to purchase it.

3. Assembly

In general, assembling a product is an error-prone process. It often has a long learning curve. Often each product has its own instruction which is recorded in a printed document. Let's take a store as an example.

When a new season arrives, there will often also be new furnishing. By offering an augmented reality app a supplier of store interior can distinguish themselves. By means of smart glasses or other devices the employees can see the physical space around them. The device then shows exactly the assembly instructions they need to follow, for example, to assemble a mannequin. These instructions can be in the form of text but also in 3D models or audio.

Because of the solution, the assembly process takes place faster. In addition, the error rate also goes down.